Everything requires examining. A student is examined through different theoretical and practical tests, an employer is tested through interviews before he or she is hired for a job; life itself acts as an examiner who is putting us through thousands of tests. The real purpose of a test is to find out if the person is safe to be carried to the next level.

A non-living object that is usable by people also runs through different tests. A toy, after being manufactured, runs through several tests to see if it can be brought to the market for selling. A smartphone, a computer, a car—every sophisticated thing in this world needs to run through different tests because if anything goes wrong inside them, it can bring drastic consequences. You would not believe it if I told you that even an object as simple as a pipe has to run through some complex examinations.

One of them is a gas tightness test, which is an extremely crucial test for a pipe that is or will be used in the future.

What is a gas tightness test?

A gas tightness test is a gas safety test for a property’s pipework where the gas pressure inside them is examined. This helps in detecting possible leaks in the pipeline while determining its integrity before being commissioned.

Certain media are used in this test depending on the category of pipeline being tested. It can be air, water, or oil.

How to perform a gas tightness test?

These tests are usually done under the supervision of an expert on various gas tests. That’s because you can do a million tests if you want but you also need to have a vague idea of what the results are implying. However, in case you do not find anyone nearby to help you or at least, enlighten you about the process and the results, check out this handy procedure.

1) A common mistake people do when gas tightness testing is that they do not keep every single gas appliance in the household turned on. This is very common in rich families who use a lot of gas-related devices and therefore, easily miss switching on a particular one.

Other than rich families, many families have the wrong idea that keeping the appliances turned on while testing is a forbidden task as it is considered dangerous. This is also a common mix-up between gas and electrical appliances. Of course, it is highly advised to keep any electrical appliances turned off even in the gas tightness test but if you keep the gas ones off, how will the gas flow through the pipework and how will you measure the tightness?

Many gas appliances, such as heaters or furnaces, use electricity to allow gas flow inside them. For those, you will have to take the risk of keeping them on if you want to accurately perform the gas tightness test. Otherwise, you can always wait for a professional.

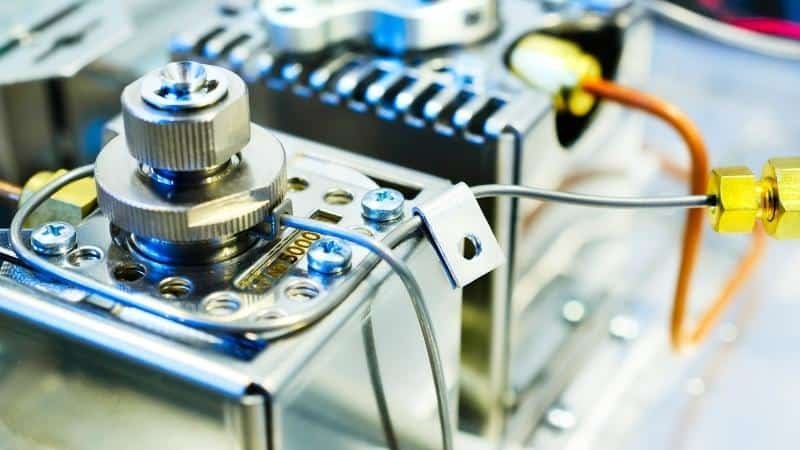

2) The instrument you will be using now to measure the gas pressure is called a test gauge. Connect the hose to the pipework very tightly so that no gas can come in or out. Make sure the hose is healthy and has no possible leakage, and the gauge meter has water within it and has been set up to zero. Last but not the least, turn off the main gas supply whenever connecting another instrument or equipment to a gas pipe system.

3) Connect the test gauge to the hose. Then you need to check if the emergency control valve in the pipework is working properly. You can do this by slowly opening the valve while observing the meter in the gauge. You should wait for a reading of 7-10 Millibar and then leave them for 1 minute to settle down. This will help you to get the correct reading for the tightness test which we will do in the next step.

4) Start the tightness test by again slowly releasing the emergency control valve. Wait for the meter to reach a pressure between 20-21 Millibar and leave for 1 minute. This allows the pipework temperature to stabilize.

5) Now it’s time to check the tightness. If the meter constantly shows a reading between 20-21 Millibar, that indicates the pipework is gas-tight and therefore, has no possible unfortunate gas leakages. You can measure the standing pressure next by slowly but fully opening the emergency control valve. A reading of 23-25 Millibars is normal for a gas system pipework.

If you have a different range of readings from the aforementioned ones, you should consider leakage or any other technical problems existing in them. Any gas appliance technician can help you in these situations.